For frequent flyers, navigating terminals, security, and boarding is second nature. You can even adjust your flying habits based on the airport and airline.

But for both seasoned and trainee travellers, flying still holds its mysteries.

Particularly the airplanes.

For example, those tiny holes in airplane windows? They’re called bleed holes. They regulate the pressure between the windowpanes.

You might have also experienced a lightning strike while flying. But thanks to what is called the Faraday cage principle, passengers are kept safe because the electricity is conducted around the metal body of the airplane.

And the heart of an airplane? First, there is not just one. Airplanes can have two to four and their beat might start with a whir, accelerate with rumble, and cruise with hum.

It’s the beat of an aircraft engine.

The heart of an airplane

Most airplanes wear their hearts on their sleeves, tucked under the two front wings. The commercial civil aircraft you took on your last trip likely had four.

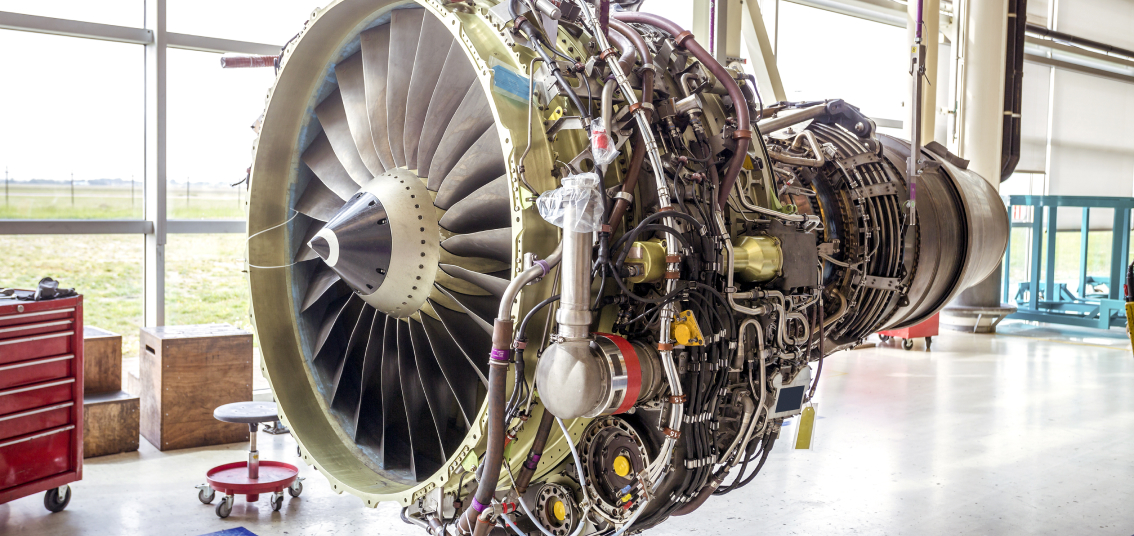

Aircraft engines can have hundreds to even thousands of individual parts. Once assembled, an engine looks like a vital organ ready to be transplanted.

But before transplanting comes transporting. And transporting the heart of anything takes some know-how.

“They used to be called the fifth engine,” explains Nicki. “Because they would affix the engine under the wing, close to the body.”

Affixing a “non-live” engine, as Nicki describes it, adds extra weight, and drag to the aircraft. This way of transporting is limited to select aircraft types and nowadays, is rarely used. Most engines are transported along with other freight inside the plane itself.

But who is Nicki?

Nicki and her most important work with engines

Alongside engineers, pilots and mechanics making your last flight possible, there is also Nicki—an Engine Logistics Expert.

Engine Logistics Experts are the unsung heroes of aviation. They work behind the scenes orchestrating the transport and maintenance of these magnificently complex, mechanical hearts.

Heart work, metaphorically or otherwise, puts one thing at the centre:

“Human safety,” Nicki states with conviction.

This, she says, is the most important part of her work. It plays a role in how she coordinates detailed maintenance procedures and in her final approvals for an engine to be shipped.

And in the cases where an emergency happens, Nicki is part of the response team.

“In logistics, we call it an AOG, aircraft on the ground, which qualifies the situation as an emergency,” Nicki explains. And regardless of the time of day, this is when she receives a call.

Aircrafts that are unintentionally grounded could be transporting a variety of things that render the situation to emergency status. The freight could be time- and temperature-sensitive pharmaceuticals, semiconductor products, or dangerous goods. There could be passengers on board.

“I am in constant communication with the engineers and technical personnel to get the needed engine part to the aircraft,” explains Nicki.

The procedures and timelines are strict and Nicki knows them in and out.

The heart of the matter: engine logistics and flying

It’s a science and an art, engine logistics. It’s work that requires a fundamental understanding of the mechanics of aircraft engines, a keen eye for detail, and a talent for problem-solving and communication in moments of escalation.

For Nicki, who got her start as a sound engineer before entering logistics in freight forwarding operations, says the jump to working in engine logistics put her life into hyper drive. “I always wanted to specialise,” she says. “This type of work helps you understand what’s actually going on when you fly.”

And the next time you fly, you’ll know some of those going-ons too.

This is a series about people in logistics. From a perishables expert calculating the fresh delivery of your fruit to a semiconductor logistics operator arranging the save arrival of a chip for your new tablet. It’s the role of logistics in your everyday life.

Read more stories like this here.